Shipbuilders in the Navy shipyards faced a high risk of developing asbestos-related diseases. Shipyards were especially dangerous from the 40s to the 60s before the dangers of asbestos use were fully understood.

These years, they used asbestos in the entire shipbuilding process and on the ships, from the engine room to the kitchen.

All the workforce in shipyards who helped build or repair such ships and the ship's personnel who spent months at sea on such vessels faced an increased risk for asbestos-related pulmonary diseases.

The construction work of the vessels implied installing and removing items containing asbestos, operations that created large amounts of dust through cutting and shaping materials during production activities. Molders were directly exposed to asbestos products and inhaled the toxic fibers daily.

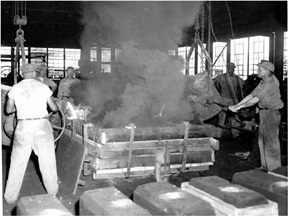

Foundry workers made certain body parts of the ships and diesel motor parts. Molders were responsible for manufacturing and repairing custom parts such as propellers, providing naval castings, and producing many different cast products in various metals necessary in the building process. Working with metals at high temperatures and due to the constant contact with high temperatures in the foundry, they had to wear safety equipment that contained asbestos. The same high-temperature factor often causes deterioration of the protective gear, resulting in the release of asbestos fibers in the air.

Molders Risked Asbestos Inhalation

Pouring molten metals needs heat-resistant crucibles, and to withstand extreme temperatures, the containers were also made with asbestos. Molders and all foundry workers were exposed yet to another source of asbestos inhalation, aggravated by the hot vapors in the foundry.

Many pieces of foundry equipment incorporated asbestos including:

- tanks

- pumps

- valves

- ovens

- boilers

- furnaces

- gaskets

- equipment manufactured before 1980

These types of equipment were insulated with asbestos and had hot tops made with asbestos to cover the tanks, increasing exposure to asbestos-containing materials and putting the personnel at risk. The workers had to wear asbestos gloves and aprons to handle them, escalating further the risks of asbestos exposure.

Additionally, foundry workers and molders may have been exposed to asbestos particles inhalation when asbestos-containing machinery was installed, repaired, or replaced. Working with asbestos-containing machinery or materials was an ongoing risk for asbestos exposure in the foundry - especially when not wearing face masks or using respiratory devices while working. Asbestos particles likely settled on their clothing, leaving foundry workers and families at even greater risk of inhaling asbestos.

What Can Molders/Foundry Workers Affected by Asbestos Exposure Do?

The best is to call the doctor and schedule a screening. If you are experiencing any of the following symptoms, please seek professional help:

- pain in the chest or abdomen

- dry cough

- shortness of breath

- respiratory system complications

- night sweats

- fatigue

- general weakness

- unintentional weight loss

Illnesses derived from asbestos exposure have a long latency period, and because of it, they often go undetected until they develop advanced stages. Asbestosis and mesothelioma can often be misdiagnosed in their early stages, so asking for a second or even a third doctor's opinion outside the VA is advisable. Your doctor can diagnose you more accurately with information about your employment history.

If you or a family member has developed an asbestos-related cancerous illness due to asbestos exposure while working as a molder/foundry worker, you may want to consult with an experienced attorney. We can connect you with the right attorneys to get advice on your rights and options given your specific circumstances.